EthicalChem’s Surfactant Technologies

The patented surfactant enhanced remediation treatments, SEPR® (Surfactant Enhanced Product Recovery) and S-ISCO® (Surfactant-enhanced In Situ Chemical Oxidation) are innovative, environmentally friendly technologies that can enhance remediation efforts.

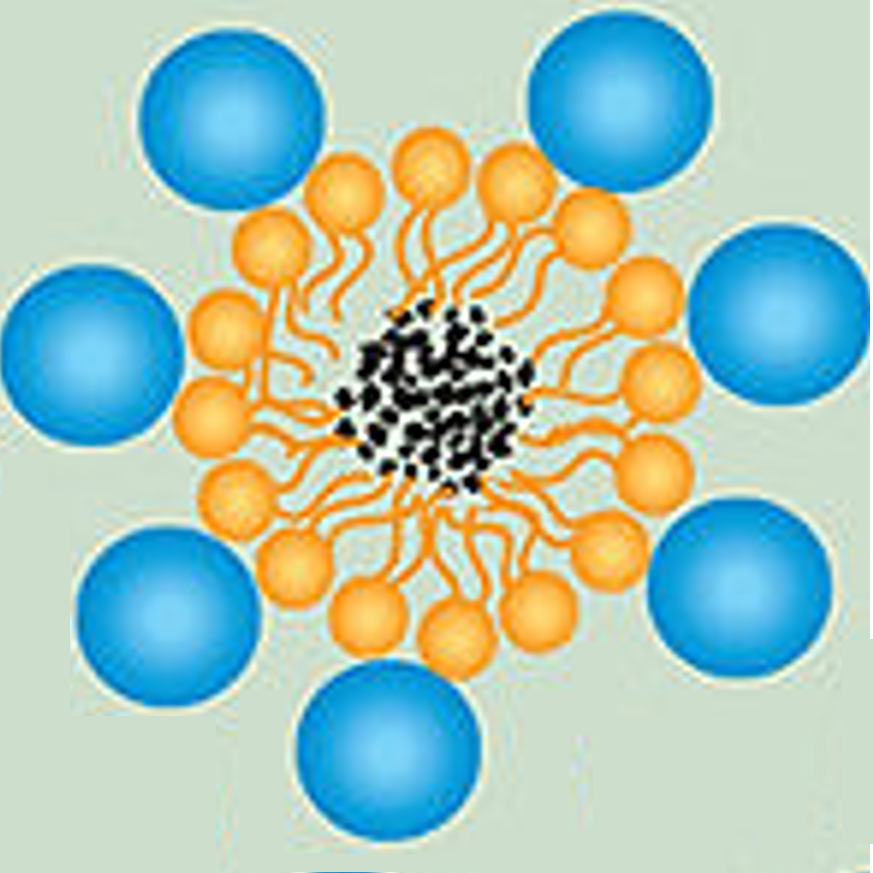

EthicalChem’s plant-based surfactants reduce interfacial tension between the water phase and immiscible organic contaminants, sweeping contaminants from soil surfaces. The surfactants form micelles which encapsulate the organic constituents, converting them to the aqueous phase which significantly increases their availability to extraction or in-situ remediation reagents.

Surfactant-enhanced In Situ Chemical Oxidation (S-ISCO)

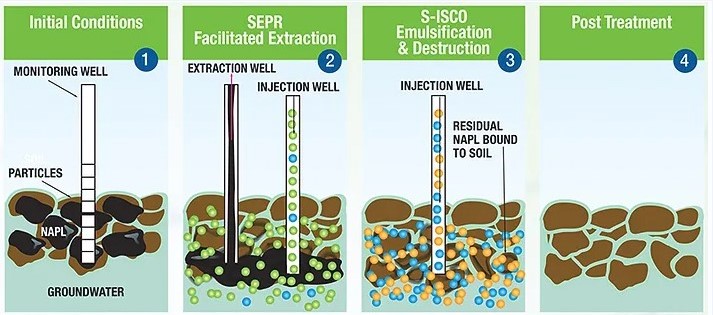

Surfactant-enhanced In Situ Chemical Oxidation (S-ISCO) technology is designed to treat tightly sorbed, hydrophobic contamination and residual non-aqueous phase liquid (NAPL) contamination in subsurface soils. By addressing the source of contamination, S-ISCO eliminates the potential for rebound and provides a permanent solution for contaminated sites.

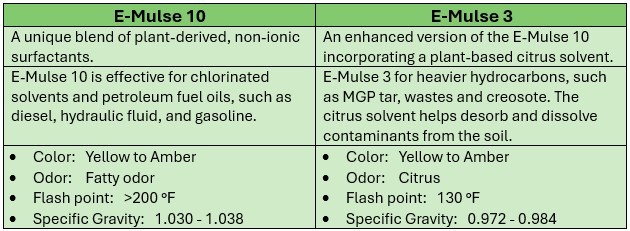

The S-ISCO process combines an EthicalChem E-Mulse biodegradable, plant-based surfactant/co-solvent mixture with an oxidant to destroy soil contamination in-place. E-Mulse surfactants desorb contaminants from subsurface soils by effectively emulsifying them into the aqueous phase, thereby greatly increasing the contaminant surface area exposed to the oxidants, making them substantially more accessible for oxidative destruction.

The S-ISCO process combines an EthicalChem E-Mulse biodegradable, plant-based surfactant/co-solvent mixture with an oxidant to destroy soil contamination in-place. E-Mulse surfactants desorb contaminants from subsurface soils by effectively emulsifying them into the aqueous phase, thereby greatly increasing the contaminant surface area exposed to the oxidants, making them substantially more accessible for oxidative destruction.

Surfactant Enhanced Product Recovery

Surfactant Enhanced Product Recovery (SEPR™) is an innovative, green chemistry technology for remediation of non-aqueous phase liquids (NAPL) in subsurface soils. SEPR combines the patented, plant-based and biodegradable surfactant and co-solvent blends, with or without low concentrations of hydrogen peroxide, in an injection-and-extraction process that allows substantial removal of free-product and residual NAPL from the subsurface. The surfactants desorb and reduce the viscosity of the NAPL, enabling greater mobility and recovery from extraction wells. When peroxide is used, its decomposition releases oxygen gas, creating bubbles which helps loosen the NAPL and facilitates movement of the free product toward extraction points.

Surfactant selection is the most important part of implementing surfactant enhanced technologies. The optimal surfactant will maximize results and cost effectiveness of the treatment. A surfactant well suited to specific site conditions can result in enhanced product recovery or make product/contaminants more available for ISCO and bioremediation.

Surfactant Product Examples

Terra Systems provides surfactant screening tests for all types of sites with rapid turnaround to optimize remediation approaches with Surfactant Enhanced Product Recovery (SEPR), Surfactant-enhanced In-Situ Chemical Oxidation (S-ISCO) and surfactant treatments. Reagent selection can focus on providing desorption of contaminants or NAPL from soil, reducing viscosity of NAPL, or creating either a stable or unstable emulsion of contaminants with the groundwater.

Terra Systems provides surfactant screening tests for all types of sites with rapid turnaround to optimize remediation approaches with Surfactant Enhanced Product Recovery (SEPR), Surfactant-enhanced In-Situ Chemical Oxidation (S-ISCO) and surfactant treatments. Reagent selection can focus on providing desorption of contaminants or NAPL from soil, reducing viscosity of NAPL, or creating either a stable or unstable emulsion of contaminants with the groundwater.

Case Study

ISOTEC Case Study#118 DOD Facility, New Mexico

Combined Surfactant and ISCO Pilot Program of Petroleum Hydrocarbon Impacted Groundwater.

Product Information

SEPR® (Surfactant Enhanced Product Recovery)

S-ISCO® (Surfactant-enhanced In Situ Chemical Oxidation)

Safety Data Sheets

For additional information contact: Tim Pac, Senior Remedial Engineer – tpac@terrasystems.net (508) 440-9348